Due to its focused and extremely qualified on-web site R&D groups and specific pilot workshops, Unither has the know-how, gear and expertise to control merchandise growth through the earliest phases.

BFS machines, like shuttle and rotary styles, present benefits around common vials concerning filling and producing procedures, with shuttle equipment enabling for the usage of insertion technology.

The procedure begins with heating pharmaceutical-grade resin, and extruding it right into a parison, and that is then molded into a certain container form. This container is quickly filled with liquid medication, ensuring the very best volume of sterility and product integrity.

The performance of BFS permits each substantial and compact orders being fulfilled with trustworthy high-quality at significant speeds and volumes. The aseptic BFS filling approach enables a single device to execute a ongoing sequence of automatic functions to mildew plastic containers from molten resin (LDPE in ApiJect’s case), fill the containers with sterile liquid, then awesome and seal them in below a few seconds.

For decades, We now have specialised in creating generic respiratory medications utilizing BFS. Our West Columbia amenities are built to make numerous billion doses yearly of inhalation solutions and various sterile compounded prescription drugs.

The molds are cooled, but you do must choose that into account once you style your facility. Nowadays, you may provide the item proper to The purpose of dosing at a selected temperature.”

Use our information for assist in choosing the sealing Remedy that most accurately fits your requirements and prerequisites.

This seamless producing method is complemented by an engraving procedure for critical info including drug products details, plus a protecting foil that guarantees airtight sealing for best-notch item protection.

Pauzer claimed that it can help, significantly for the increased density plastics. With decreased density resins/plastics, there is a lot more opaqueness which makes it tricky for automated programs.

Various waters and compact molecule medications are the traditional goods filled in the parts of IV and irrigation remedies, ophthalmic OTC and medicines, nebulized inhalation medicines, and smaller volume injectable products and solutions.

This innovation ensures the best standards of sterility and efficiency which happens to be critical for creating Protected and successful pharmaceuticals. BFS supports the creation of a various choice of health care solutions, such as ophthalmic medicines and parenteral vaccines.

Plastics tie up less more info means than glass in the course of output and disposal. In addition, considerably less CO2 is manufactured because the transport body weight is lower and no empty containers are transported.

Each and every Conference includes shows on a wide array of BFS associated subjects by major market gurus (equally operators and suppliers). Users get to listen to displays on the latest developments in BFS similar technology and greatest methods. The conferences also routinely include a tour of one of our member’s web pages which usually proves very popular and informative.

Catalent has undertaken in depth study into the stability of biologics going through here BFS, to review any possible compatibility issues that the procedure might have over the molecule or distinctions within the BFS container in comparison with glass. A comprehensive review was carried out using a design monoclonal antibody formulation inside its ADVASEPT system, with glass vials with uncoated stoppers used as controls.Various parameters of amonoclonal antibody’s-physical Houses, along with steadiness, potency, and observable leachables had been testedand calculated more than a 9 thirty day period period.

Shaun Weiss Then & Now!

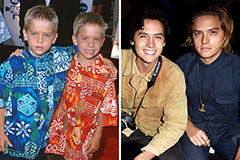

Shaun Weiss Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Ross Bagley Then & Now!

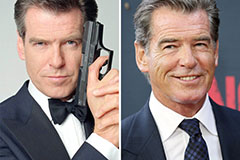

Ross Bagley Then & Now! Pierce Brosnan Then & Now!

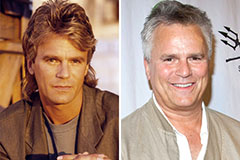

Pierce Brosnan Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!